July 28, 2025

Augmented reality in engineering - a new era

Founder/CTO The Spatial Studio, Technology-Enthusiast

Today, engineers and employees at engineering companies are benefiting from augmented reality. They can use digital models to anticipate production challenges or showcase virtual products for marketing purposes. Read our article on AR in engineering to find out how this works.

Augmented Reality (AR) is an innovative technology that superimposes digital information on the real world to enhance the user's perception and interaction with their environment. This merging of the virtual and real worlds offers unique benefits and opportunities in a variety of fields, particularly in engineering.

- Increased efficiency through AR: Augmented Reality enables faster and more accurate maintenance of machinery in the engineering industry, reducing downtime by up to 30%.

- Cost savings and ROI: Companies using AR technologies report average cost savings of 20% in training and maintenance processes, ensuring a high return on investment.

- Improve collaboration and reduce errors: AR enables engineers and technicians to collaborate in real time, reducing errors in complex projects by up to 25% and improving product quality.

Augmented Reality

The concept of augmented reality is several decades old. Its origins lie in the early developments of computer graphics and head-mounted displays in the 1960s, but it was not until the late 20th and early 21st centuries that advances in computing power, graphics processing and mobile technologies made AR technology more relevant.

Today, AR is a rapidly growing field with widespread applications in industries such as manufacturing, healthcare, retail and education.

The importance of AR in engineering

Augmented Reality (AR) has become an important technology in mechanical engineering, significantly improving various aspects of the field. Its ability to overlay digital information onto the physical world brings numerous benefits and makes it an indispensable tool for engineers.

Better design and prototyping

AR enables engineers to visualise and interact with 3D models of mechanical components and systems in a real-world context.

- It provides a clear understanding of how a design will fit and function in its intended environment.

- It enables interactive design reviews where stakeholders can visualise changes in real time, facilitating communication and collaboration.

- Fewer physical prototypes are required.

Improve Maintenance and Repair Processes

Maintenance and repair in mechanical engineering is often a complex operation that requires precise execution.

- Visual step-by-step instructions that can be overlaid on physical equipment help technicians perform tasks.

- Remote experts can provide real-time support to on-site technicians through AR interfaces.

Advances in training and education

The use of AR in education and training provides an immersive and interactive learning experience for engineering professionals.

- Realistic simulations that allow learners to practice and refine their skills.

- Interactive tutorials and hands-on experiences that can be adapted to different learning levels and needs.

- Facilitates distance learning.

Improving safety

Safety is a key issue in mechanical engineering, as the operation of machinery and equipment can pose significant risks.

- Potential hazards are identified and highlighted in real time.

- Simulation of emergency scenarios helps personnel prepare for real-life incidents.

- Instant access to safety protocols and policies via AR interfaces.

AR tools and technologies in engineering

The use of Augmented Reality (AR) in engineering is based on a combination of advanced hardware and software tools. These technologies work together to create interactive and immersive experiences.

AR hardware

- Headsets and glasses: Devices such as Microsoft HoloLens, Magic Leap and Apple Vision Pro provide hands-free AR experiences that allow engineers to interact with digital overlays. These devices are equipped with sensors, cameras and displays that provide real-time data and instructions.

- Mobile devices: Smartphones and tablets are often used for AR applications due to their portability and accessibility. Devices such as the Apple iPhone and various Android models support robust AR experiences with dedicated apps.

- Projection-based systems: These systems use projectors to project digital information directly onto physical objects or surfaces. They are suitable for large-scale applications, such as visualising mechanical systems on factory floors or in assembly processes.

AR software and applications

AR software is essential for creating, managing and displaying AR content.

- CAD and simulation software: Integrating AR into computer-aided design (CAD) software such as Autodesk Fusion 360, SolidWorks and PTC Creo allows engineers to visualise and manipulate virtual prototypes in real-world environments.

- AR development platforms: Platforms such as Unity, Unreal Engine and ARKit (for iOS) provide the tools to create your own AR applications. These platforms offer features such as spatial mapping, object recognition and real-time rendering.

Integration with other technologies

AR technology in engineering is often combined with other advanced technologies.

- Internet of Things (IoT): The combination of AR and IoT enables real-time monitoring and visualisation of data from connected devices and sensors.

- Artificial Intelligence (AI): AI enhances AR applications through advanced data analysis, pattern recognition and decision support.

Case Studies and Practical Applications

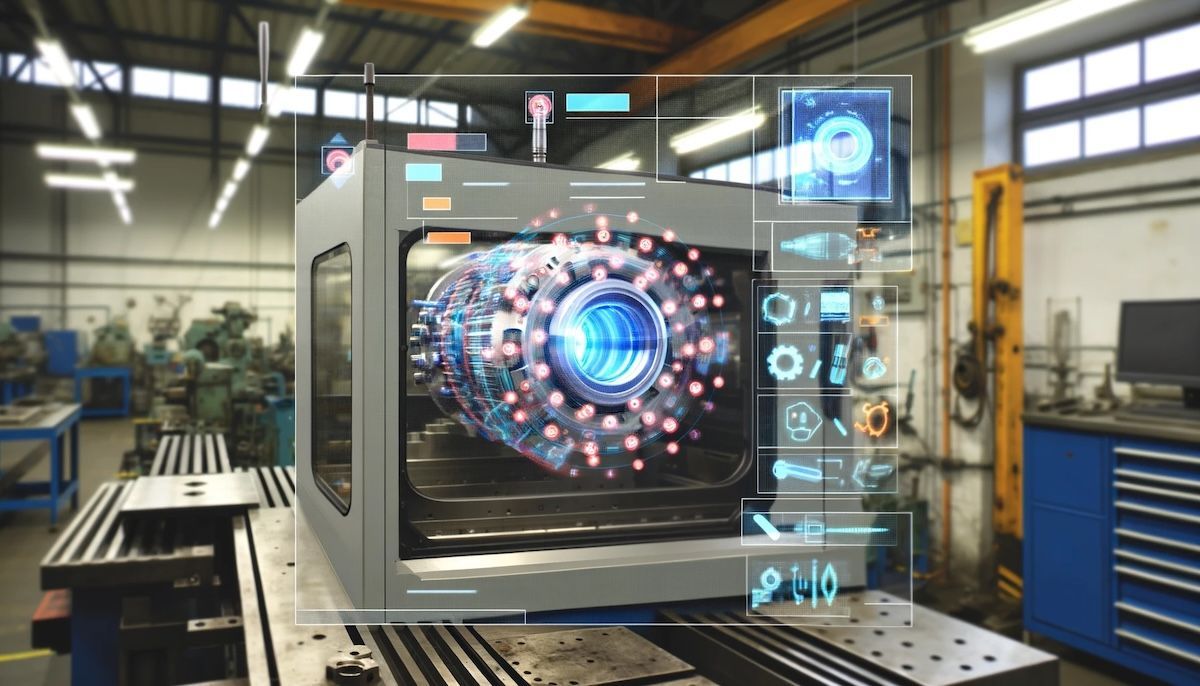

Augmented Reality (AR) has shown its potential to transform the engineering industry through a number of practical applications.

Practical application: Automotive

In the automotive industry, companies such as BMW and Volkswagen are using AR to improve the design and prototyping of new vehicle models. Engineers can project digital models of car parts and assemblies onto physical models, allowing them to test fit and function before production.

Case Study: AR-based maintenance solutions from Siemens

Siemens has adopted AR solutions to improve maintenance and repair processes for its industrial machinery. Technicians equipped with AR headsets receive step-by-step visual instructions overlaid on the machine, guiding them through complex repair tasks.

Case study: Caterpillar's AR training programmes

Caterpillar, a leading manufacturer of construction and mining equipment, is using AR to train its employees. AR applications provide immersive training modules where employees can interact with virtual machine models, practice workflows and solve common problems.

Real-world applications: Construction industry

In the construction industry, AR is used to increase safety on construction sites by visualising potential hazards and simulating emergency scenarios. With AR, workers can see virtual safety barriers, identify safety zones and receive real-time alerts about nearby hazards. In addition, AR and BIM provide architects with interactive insights into construction.

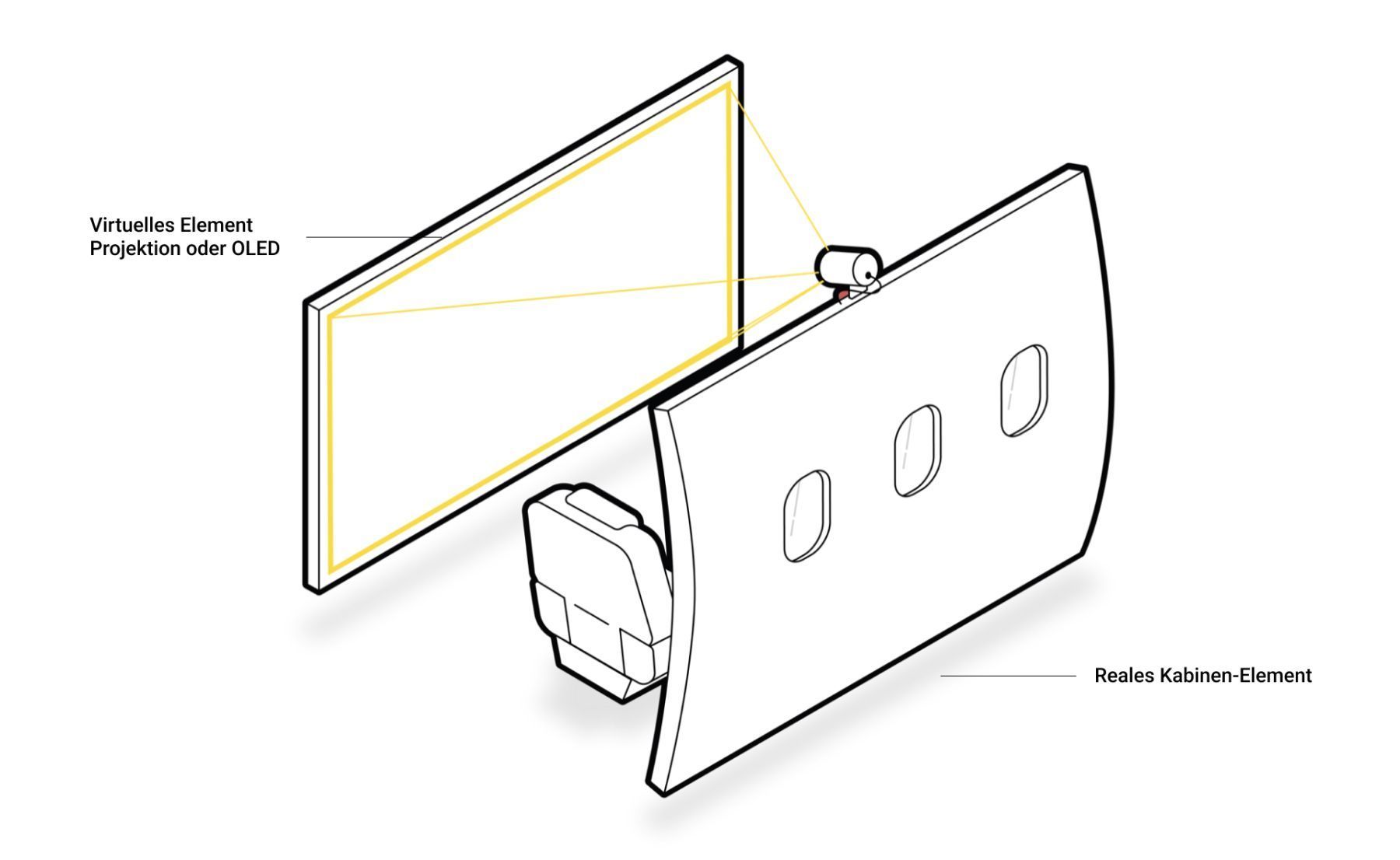

Marketing application: trade shows

At trade shows, engineering companies can use AR to give potential customers an insight into their products. A dedicated AR app could, for example, show a machine that extends well beyond the space available on the stand.

Lufthansa Technik has already used the technology to showcase its products. We created a virtual cabin mockup (digital twin) that was used at trade shows.

Example

Advantages of AR in Mechanical Engineering

Integrating augmented reality (AR) into mechanical engineering offers a number of benefits that significantly improve various aspects of the engineering process.

Increased Efficiency and Productivity

AR streamlines and accelerates many engineering processes, resulting in increased efficiency and productivity:

- Improved design processes

- Streamlined maintenance and repair

- Improved training programs

Reduced errors and rework

AR helps minimize errors and rework by providing precise and accurate information:

- Real-time visualization

- Precise maintenance instructions

Enhanced collaboration and communication

AR enables better communication and collaboration among engineering teams and stakeholders:

- Interactive design reviews

- Remote assistance and support

Cost savings and ROI

The use of AR in mechanical engineering results in significant cost savings and a high return on investment:

- Lower prototyping costs

- Lower maintenance costs

- Lower training costs

Challenges and Limitations

Although Augmented Reality (AR) offers many benefits, its implementation is not without challenges and limitations.

Technical limitations

- Hardware limitations: AR hardware such as headsets and glasses often have issues with battery life, processing power, and ergonomics.

- Software compatibility: Integrating AR into existing software systems such as CAD and simulation tools can be complex and require extensive customization.

- Field of view and resolution: Current AR devices often have limited field of view and resolution.

Implementation Costs

- Initial investment: The cost of acquiring and implementing AR technology can be high, including the cost of hardware, software, and training.

- Maintenance and upgrades: AR technology is rapidly evolving and requires regular updates and maintenance to ensure optimal performance.

User adoption and training

- Resistance to change: Engineers and technicians accustomed to traditional methods may be reluctant to adopt AR technologies.

- Learning curve: Adoption of AR technology requires extensive training programs to ensure users can effectively operate AR devices and applications.

Data security and privacy concerns

- Sensitive information: AR applications often use sensitive technical data, including proprietary designs and operational details.

- Network vulnerabilities: AR solutions that rely on cloud-based services or real-time data transmission are vulnerable to network vulnerabilities and cyber threats.

Future trends and developments

The future of augmented reality (AR) in mechanical engineering looks promising. As this technology continues to evolve, it is expected to become more deeply integrated into technical processes, driving innovation and increasing efficiency.

Advances in AR hardware

- Improved AR headsets and glasses: Future AR hardware is expected to feature better ergonomics, longer battery life, a larger field of view, and higher resolution.

- Haptic feedback and tactile interfaces: The integration of haptic feedback into AR systems allows users to “feel” digital objects, which improves the interaction and manipulation of virtual models.

Improved software functionality

- Integration of AI and machine learning: The integration of artificial intelligence (AI) and machine learning (ML) will enable more sophisticated data analysis, predictive maintenance, and automatic design optimization.

- Advanced simulation and modeling: Future AR software will offer more advanced simulation capabilities that will allow engineers to test and visualize complex mechanical systems under various conditions.

New applications and innovations

- Smart factories and Industry 4.0: AR will play a crucial role in the development of smart factories, where connected systems and automated processes increase production efficiency.

- Personalized and adaptive training: AR-supported training programs will become more personalized and adaptable by tailoring content to the needs and knowledge level of individual learners.

Conclusion

By overlaying digital information onto the physical world, AR provides engineers with powerful tools to visualize, interact with, and optimize complex mechanical systems in real time.

The case studies and practical applications presented in this article illustrate the significant impact of AR on various aspects of mechanical engineering. From increasing efficiency and productivity to reducing errors and rework, AR is proving to be an invaluable asset. In addition, the technology facilitates collaboration and communication, leading to more informed decisions and better outcomes.

Companies in the industry must undergo rapid change (digital transformation) to keep pace with the competition. Augmented reality offers an opportunity to differentiate and set new standards.

Smart factories and Industry 4.0: AR will play a critical role in the development of smart factories, where connected systems and automated processes increase production efficiency.

Personalized and adaptive training: AR-based training programs will become more personalized and adaptive, tailoring content to the needs and skill levels of individual learners.

Integration of AI and machine learning: The integration of artificial intelligence (AI) and machine learning (ML) will enable more sophisticated data analysis, predictive maintenance, and automated design optimization.

Founder and CEO

Passion for New Technologies

As a creative engineer and consultant specializing in holistic digital transformation, I have spent over 15 years helping renowned companies use new and innovative technologies in creative and meaningful ways.

At "The Spatial Studio," my team and I combine engineering expertise, software development, and UX design to create entirely new three-dimensional possibilities for our clients.